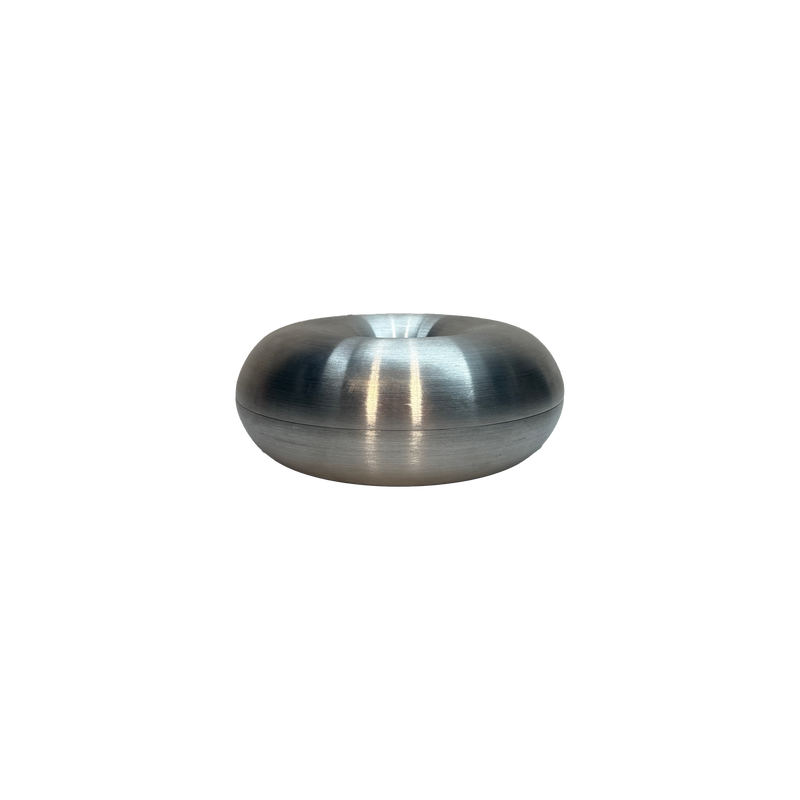

When space is tight and precision matters, our tight radius aluminium donut halves are the go-to solution for high-end intercooler and intake fabrication. Designed for professional fabricators and serious car builders, these donut halves allow you to create ultra-compact bends without sacrificing airflow or fitment.

Engineered for Tight Spaces

Featuring a 0.75D bend radius, these donut halves make it possible to route piping where standard mandrel bends simply won’t fit. Perfect for modern engine bays, turbo setups, and custom intake layouts where every millimetre counts.

Manufactured from 5052 aluminium spun from 2mm sheet, they offer excellent strength, corrosion resistance, and outstanding weldability. The precision spinning process ensures clean edges and accurate geometry, resulting in no gaps during fit-up—saving you time during fabrication and delivering cleaner welds.

Ideal For

✔ Intercooler piping

✔ Intake systems

✔ Tight engine bay layouts

✔ Custom turbo and performance builds

Key Features

-

0.75D tight radius for compact, space-saving bends

-

Spun from 5052 aluminium for strength and corrosion resistance

-

2mm wall thickness – strong yet easy to weld

-

Donut halves for custom bend angles and smooth transitions

-

Precision fit-up with no gaps for cleaner welds

Why Choose Our Aluminium Donut Halves?

✔ Trusted by professional fabricators

✔ Allows custom angles not possible with standard bends

✔ Reduces fabrication time and rework

✔ Ideal for high-flow intercooler and intake systems

Build tighter, cleaner, and smarter. Add to cart now and take full control of your intake and intercooler fabrication.